文章來源:《國資報告》雜(za)志 發布時間:2022-05-10

2020年12月(yue)27日(ri),京(jing)雄城際鐵路全線開通運(yun)營(ying),雄安(an)站同(tong)步(bu)投入(ru)使(shi)用(yong)。作為雄安(an)新區首個重大基礎設施項目,這(zhe)一(yi)線路運(yun)營(ying)后,北京(jing)西站到(dao)雄安(an)新區最(zui)短僅(jin)需50分鐘,雄安(an)新區的發展將(jiang)步(bu)入(ru)快車道(dao),京(jing)津冀協同(tong)發展也將(jiang)得到(dao)新的重要支(zhi)撐。

京雄(xiong)鐵路意義重大,中(zhong)央(yang)企業(ye)勇挑(tiao)重擔。包(bao)括中(zhong)國中(zhong)鐵、中(zhong)國鐵建(jian)、中(zhong)建(jian)集團、中(zhong)交集團等(deng)基建(jian)狂魔(mo)等(deng)在(zai)內的(de)諸多(duo)央(yang)企是沿線鐵路、場站建(jian)設的(de)主力軍。

其中(zhong)(zhong)(zhong),中(zhong)(zhong)(zhong)國(guo)中(zhong)(zhong)(zhong)鐵(tie)承(cheng)擔了雄安(an)站、大興(xing)機場站、北落店(dian)村全封(feng)閉聲屏障工程(cheng)、雄安(an)站特大橋等(deng)關鍵節點和(he)重要工程(cheng)的建(jian)設任務(wu)。建(jian)設過(guo)程(cheng)中(zhong)(zhong)(zhong),中(zhong)(zhong)(zhong)國(guo)中(zhong)(zhong)(zhong)鐵(tie)面對工期緊張、疫情沖擊等(deng)不(bu)利影響,勇于擔當,積極推進技術(shu)創(chuang)新和(he)管(guan)理創(chuang)新,踐行綠色與智(zhi)能(neng)理念。

2019年1月16日,中(zhong)(zhong)共中(zhong)(zhong)央總書(shu)記、國家主席、中(zhong)(zhong)央軍委主席習近平在河北雄安新(xin)區考察調研期間(jian)勉勵大(da)(da)家說,“城市建設、經(jing)濟發展(zhan),交通要先(xian)行,你(ni)們(men)正在為雄安新(xin)區建設這(zhe)個(ge)‘千年大(da)(da)計’做(zuo)著開(kai)路先(xian)鋒的工作,功不(bu)可(ke)沒。”

與習近(jin)平總書(shu)記連線(xian)的(de),正是(shi)中國中鐵(tie)九局(ju)京(jing)雄(xiong)(xiong)城際鐵(tie)路雄(xiong)(xiong)安(an)站的(de)建設(she)者。兩年(nian)來,中國中鐵(tie)時刻牢記總書(shu)記囑托,努(nu)力(li)在(zai)創造“雄(xiong)(xiong)安(an)質(zhi)(zhi)量”上下功夫(fu)(fu),努(nu)力(li)“在(zai)推動高(gao)質(zhi)(zhi)量發展(zhan)方面成(cheng)(cheng)為全國的(de)一個樣板(ban)”上下功夫(fu)(fu),高(gao)質(zhi)(zhi)量高(gao)標準完成(cheng)(cheng)了京(jing)雄(xiong)(xiong)城際鐵(tie)路各項(xiang)建設(she)任務。

勇于擔當

京雄鐵(tie)路意(yi)義重(zhong)大,建設(she)期間又遭疫(yi)情(qing)沖(chong)擊(ji),時間緊、任務重(zhong)、標(biao)準(zhun)高、壓(ya)力(li)大。面對這一特殊任務,中國中鐵(tie)各參建單位牢記重(zhong)托(tuo),勇于擔當,克(ke)服了各項困難,交出(chu)了一份合格的答(da)卷。

雄安站(zhan)是雄安新(xin)區首個(ge)開工建設的重大基礎(chu)設施項目,站(zhan)場總規模13臺(tai)23線(xian),總建筑面積47.52萬(wan)平方米,相當(dang)于6個(ge)北京站(zhan),而(er)工期只有兩年(nian),具體負責的中(zhong)國中(zhong)鐵建工集團協(xie)(xie)調起數十家作業隊伍、6000余(yu)名建設者開啟大兵團協(xie)(xie)同作戰模式,2019年(nian)10月(yue)完成地下(xia)結構施工。

2020年春節前后,新冠(guan)肺炎疫情來(lai)(lai)勢迅猛(meng)。而中(zhong)國中(zhong)鐵建工(gong)集團參(can)加雄安(an)站建設的(de)施(shi)工(gong)隊伍有三(san)分(fen)之(zhi)二(er)來(lai)(lai)自湖(hu)北,無法及時返回工(gong)地。項目部找遍所有渠道,千方百計聯系全國各地能來(lai)(lai)雄安(an)的(de)施(shi)工(gong)隊伍,派(pai)出(chu)100多(duo)輛大(da)巴車,從貴(gui)州、云(yun)南、湖(hu)南、河南、安(an)徽(hui)等地接來(lai)(lai)施(shi)工(gong)隊伍。

為(wei)了(le)搶回疫情耽誤的(de)(de)工期,中國中鐵(tie)建(jian)工集(ji)團項目(mu)部在原有施(shi)(shi)工隊伍(wu)的(de)(de)基礎上,增(zeng)加新的(de)(de)施(shi)(shi)工作業隊伍(wu)、人員、機械設備等(deng),將原定的(de)(de)流水施(shi)(shi)工轉為(wei)平行施(shi)(shi)工,加快工程施(shi)(shi)工進度。項目(mu)部開(kai)展勞動競賽(sai),施(shi)(shi)工人員兩(liang)班倒,有時甚至三(san)班倒,晝夜不(bu)停地施(shi)(shi)工。70多名核心(xin)管理人員也是連軸轉,平均每天行走2萬步是常態……經過艱苦奮戰,他們1個月完成(cheng)了(le)3個月的(de)(de)工程量(liang)。

疫情(qing)同樣給中(zhong)鐵二(er)(er)局(ju)負(fu)責的K1快(kuai)速路項目帶來(lai)了(le)巨大(da)壓力。面對疫情(qing),中(zhong)鐵二(er)(er)局(ju)項目部(bu)科學防治(zhi),一手(shou)(shou)抓生產(chan)、一手(shou)(shou)抓防疫,將員(yuan)工(gong)(gong)接觸(chu)疫情(qing)的概率劃分成(cheng)紅、黃、綠三種顏色進行管理,并花費百余萬元購入集裝箱,設置11號駐地,對所(suo)有人員(yuan)實行封閉性(xing)管控,既達(da)到了(le)防控要求,又(you)保(bao)證(zheng)了(le)順利復工(gong)(gong)復產(chan)。成(cheng)為雄安新區首批復工(gong)(gong)的18個重點項目之一。

建(jian)設(she)過程中(zhong),中(zhong)國中(zhong)鐵(tie)十分(fen)注重工程質量(liang),并盡量(liang)降低對周邊居(ju)民(min)生(sheng)活(huo)的影響(xiang)。

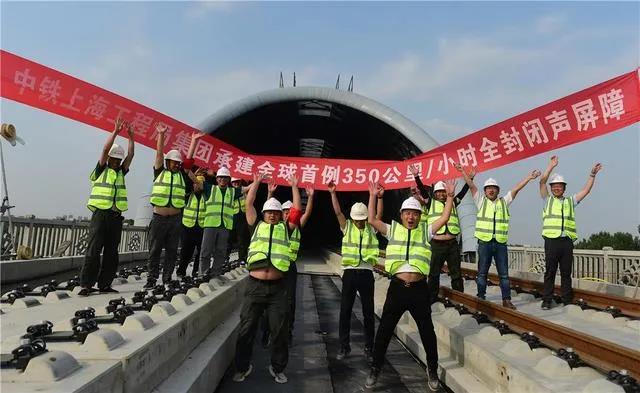

由中(zhong)國中(zhong)鐵上海工(gong)程(cheng)局建筑(zhu)公司承建施(shi)工(gong)的京雄(xiong)城際鐵路(lu)北(bei)落店(dian)村全(quan)封閉聲(sheng)(sheng)屏障工(gong)程(cheng),將最(zui)大程(cheng)度降低(di)高鐵通過居民區產生的噪(zao)聲(sheng)(sheng)。為(wei)保證(zheng)工(gong)程(cheng)質(zhi)量(liang),項(xiang)目(mu)部組織對柱腳進行(xing)(xing)(xing)了(le)高達400萬(wan)次(ci)的抗疲勞試驗(yan),相當于模擬100年內每年4萬(wan)次(ci)高鐵通行(xing)(xing)(xing)。在長達847米的主體鋼結構上,建設者們為(wei)34900余條焊(han)縫(feng)進行(xing)(xing)(xing)了(le)100%驗(yan)檢,實現了(le)焊(han)縫(feng)100%檢查合格。為(wei)確保螺(luo)(luo)栓(shuan)穩固、安全(quan)行(xing)(xing)(xing)車(che),項(xiang)目(mu)部為(wei)10440個螺(luo)(luo)栓(shuan)都編(bian)上了(le)號,讓每個螺(luo)(luo)栓(shuan)都有自己(ji)的“身份碼(ma)”,使施(shi)工(gong)質(zhi)量(liang)責任可追溯到每一個螺(luo)(luo)栓(shuan)的安裝、管理者之上,確保工(gong)程(cheng)質(zhi)量(liang)萬(wan)無一失。

為(wei)處(chu)理好村民關注的(de)(de)(de)揚塵、噪聲、污水、垃圾(ji)等(deng)問題,中(zhong)(zhong)鐵建(jian)工(gong)項(xiang)目(mu)(mu)部成(cheng)立以(yi)項(xiang)目(mu)(mu)經(jing)理為(wei)組(zu)長的(de)(de)(de)環(huan)境(jing)保護(hu)領(ling)導小(xiao)組(zu),秉(bing)承“群眾利益(yi)無(wu)小(xiao)事”的(de)(de)(de)原(yuan)則,將施(shi)工(gong)中(zhong)(zhong)出現(xian)的(de)(de)(de)問題列出清單,明(ming)確解決辦(ban)法、責任人以(yi)及完成(cheng)時間,堅持文(wen)明(ming)施(shi)工(gong),打造綠色工(gong)地(di)。當(dang)地(di)村莊的(de)(de)(de)道路一到(dao)雨天就泥(ni)濘不堪,車輛無(wu)法通(tong)行(xing),村民只能步行(xing)。項(xiang)目(mu)(mu)部了解情(qing)況后(hou),投資100多萬元,對村里的(de)(de)(de)主干道進(jin)行(xing)硬化,修繕關李馬滸村水泥(ni)路約5公里。

技術創新

在(zai)建設過程中,中國中鐵探索運(yun)用了多(duo)種先(xian)進(jin)技術,在(zai)提高(gao)建設效率的同(tong)時,進(jin)一步改善工程質量。

比如(ru),雄(xiong)安(an)(an)站(zhan)建設期間(jian),河北省首(shou)個5G+邊緣計(ji)(ji)算智(zhi)(zhi)慧工(gong)(gong)地(di)(di)示(shi)范場(chang)景(jing)(jing)在(zai)中鐵建工(gong)(gong)集團雄(xiong)安(an)(an)站(zhan)項(xiang)(xiang)目部投入使用。該了解(jie),該項(xiang)(xiang)目運用5G、邊緣計(ji)(ji)算、BIM、高(gao)精度(du)定位、高(gao)清(qing)視頻通信等計(ji)(ji)算,基于(yu)5G網絡,結合邊緣計(ji)(ji)算搭建完成智(zhi)(zhi)慧工(gong)(gong)地(di)(di)整(zheng)體平臺(tai),具(ju)備了傳輸速率高(gao)、安(an)(an)全性能好的特性。此外,智(zhi)(zhi)慧工(gong)(gong)地(di)(di)系統還可以通過(guo)AR實景(jing)(jing)監控(kong)技術,實現工(gong)(gong)地(di)(di)隨(sui)(sui)時隨(sui)(sui)地(di)(di)可視化協(xie)同指揮和生產管理,監管人員、工(gong)(gong)地(di)(di)現場(chang)施(shi)工(gong)(gong)人員、專家均可以通過(guo)會議終端、移動端、電腦端多種方(fang)式,實時掌握(wo)工(gong)(gong)地(di)(di)施(shi)工(gong)(gong)狀態,隨(sui)(sui)時溝通施(shi)工(gong)(gong)方(fang)案(an)。

中鐵建工集團雄安站項目工程師祝佳(jia)伍介紹說,“通(tong)過筆記本上的智(zhi)慧工地系統,監看一(yi)公(gong)里(li)以外(wai)工地上各種實時狀況(kuang)。現場(chang)有(you)多少工人、都(dou)在什么(me)位(wei)置、塔吊(diao)的運行狀況(kuang)如何(he)、現場(chang)環境指標(biao)高低都(dou)一(yi)目了然。”

中(zhong)國中(zhong)鐵建工集團雄(xiong)安站黨(dang)工委副書(shu)記王(wang)星運說:“智(zhi)慧化技術應用(yong),無論是(shi)從安全方面(mian)還是(shi)進度方面(mian),都起到了(le)很好的(de)保障作用(yong)。”

北京(jing)大興機場站是京(jing)雄鐵(tie)路的重(zhong)要節點,也是向全世界游客展(zhan)示中國高鐵(tie)建設(she)、運營水平的重(zhong)要窗(chuang)口(kou)。

京雄鐵路大興機場站

作(zuo)為承建單(dan)位,中(zhong)國(guo)中(zhong)鐵北京工(gong)程(cheng)局項(xiang)(xiang)(xiang)目部為保證施(shi)工(gong)品質,專(zhuan)門成(cheng)立信息(xi)化(hua)中(zhong)心(xin),引入(ru)BIM技術指導施(shi)工(gong)。機場(chang)(chang)2號隧道是項(xiang)(xiang)(xiang)目部BIM技術應用的(de)最(zui)前線。面(mian)對隧道的(de)襯砌、拱形結構,技術人員第一時(shi)間形成(cheng)多維建模信息(xi),達到(dao)現場(chang)(chang)可(ke)視化(hua),實現虛擬化(hua)協(xie)同管理(li),不僅節約工(gong)期(qi)、更節約成(cheng)本。進(jin)入(ru)無(wu)砟軌道施(shi)工(gong)階段,多工(gong)序(xu)交叉、作(zuo)業空間小都成(cheng)了(le)迫在眉睫的(de)難題。項(xiang)(xiang)(xiang)目部進(jin)行4D進(jin)度模擬,無(wu)縫拼接各道工(gong)序(xu),信息(xi)人員24小時(shi)全程(cheng)跟(gen)控,硬是把90天(tian)(tian)的(de)工(gong)期(qi)壓(ya)縮到(dao)40天(tian)(tian)。

在(zai)建設全球(qiu)首個適用(yong)于時速350km/h的全封閉聲屏障工程時,項目總工程師(shi)張(zhang)騰飛翻遍(bian)了(le)國內外資料,沒有(you)找(zhao)到可以資借鑒的先例(li)。為此,項目部(bu)在(zai)施工中工程采(cai)用(yong)了(le)拱架結構(gou)整體(ti)焊接工藝、靴型柱腳(jiao)安裝工藝、高強度防脫落螺栓工藝,均為全國首創。

在(zai)(zai)京雄城際鐵(tie)(tie)路(lu)五標(biao),中(zhong)國中(zhong)鐵(tie)(tie)上(shang)海(hai)工(gong)(gong)(gong)程(cheng)局項目部則(ze)創新探索了(le)(le)中(zhong)國高鐵(tie)(tie)首段(duan)(duan)裝(zhuang)配(pei)式(shi)一(yi)體化(hua)橋梁(liang)主體工(gong)(gong)(gong)程(cheng)施工(gong)(gong)(gong)方式(shi)。“裝(zhuang)配(pei)式(shi)工(gong)(gong)(gong)藝(yi)就是后方‘造(zao)積木’,前(qian)(qian)方‘搭積木’,提前(qian)(qian)把高鐵(tie)(tie)橋梁(liang)工(gong)(gong)(gong)程(cheng)的管樁、墩身、墩帽等‘零件’進行標(biao)準(zhun)化(hua)設計,分(fen)段(duan)(duan)工(gong)(gong)(gong)廠標(biao)準(zhun)化(hua)制(zhi)造(zao),在(zai)(zai)施工(gong)(gong)(gong)現場將(jiang)它們組裝(zhuang)起來(lai)就行了(le)(le)。”中(zhong)鐵(tie)(tie)上(shang)海(hai)工(gong)(gong)(gong)程(cheng)局集(ji)團京雄城際鐵(tie)(tie)路(lu)五標(biao)項目部總(zong)工(gong)(gong)(gong)程(cheng)師侯宇飛說,“這項技術完全顛(dian)覆了(le)(le)傳統(tong)的建(jian)橋方式(shi),技術優勢十分(fen)明顯。”

“這是中(zhong)(zhong)國高(gao)鐵(tie)橋梁(liang)建(jian)設(she)技術體系的(de)一個(ge)重大突破,也是很有(you)代表意(yi)義(yi)的(de)重大創新。”中(zhong)(zhong)國國家鐵(tie)路集團有(you)限(xian)公司工管中(zhong)(zhong)心(xin)三部(bu)部(bu)長、京雄城(cheng)際鐵(tie)路指揮長楊(yang)斌(bin)說(shuo),這項技術在我國高(gao)鐵(tie)系統首次(ci)應用,在世(shi)界上也居于領先水平,以此為(wei)開端(duan),中(zhong)(zhong)國高(gao)鐵(tie)橋梁(liang)建(jian)設(she)將(jiang)走向更加綠(lv)色、智能(neng)、高(gao)效的(de)新時代。

管理創新

技(ji)術(shu)挑戰多、工(gong)(gong)程(cheng)難(nan)度大、施工(gong)(gong)周期短,要(yao)想如期完成建設(she)工(gong)(gong)作(zuo),離(li)不開(kai)先(xian)(xian)進(jin)有效的管(guan)理模式。記注意到(dao),在京雄高(gao)鐵施工(gong)(gong)過程(cheng)中,中國中鐵各參(can)建單位立足(zu)項目特點(dian),積極探(tan)索更加先(xian)(xian)進(jin)的管(guan)理方案。

按照設計要求,雄安站要大規模使用清水混(hun)凝(ning)土。所(suo)謂清水混(hun)凝(ning)土,就是通過石子(zi)、沙子(zi)、水泥配比的不同,在(zai)保(bao)證(zheng)強(qiang)度的前提下,讓建(jian)筑物呈現出自然的“高級(ji)灰”,建(jian)成(cheng)后表面基本不再進行修飾。

“清水混凝土對平(ping)整度(du)、光(guang)潔度(du)、孔眼、線條等都有(you)相當高的(de)要(yao)求,為(wei)確保施(shi)(shi)工效果,雄(xiong)安(an)站(zhan)項(xiang)目前(qian)(qian)后(hou)進行了(le)數(shu)十(shi)次(ci)(ci)樣板(ban)施(shi)(shi)工,最后(hou)使候車廳整體(ti)(ti)性、韻律性、藝術性充分展現出來(lai)。”中(zhong)國中(zhong)鐵建工集團(tuan)(tuan)雄(xiong)安(an)站(zhan)項(xiang)目總工程師(shi)吳亞東介紹說。在清水梁、柱施(shi)(shi)工前(qian)(qian),中(zhong)鐵建工集團(tuan)(tuan)項(xiang)目團(tuan)(tuan)隊(dui)(dui)多方案(an)對比,最終選定(ding)契(qi)合生產特點的(de)定(ding)型鋼(gang)(gang)模板(ban)體(ti)(ti)系及定(ding)型鋼(gang)(gang)木組合模板(ban)體(ti)(ti)系。為(wei)驗證混凝土與鋼(gang)(gang)模板(ban)特性,項(xiang)目團(tuan)(tuan)隊(dui)(dui)數(shu)次(ci)(ci)調(diao)整砂(sha)率、外加劑、水含量等數(shu)值以摸索最佳配比。通過數(shu)十(shi)次(ci)(ci)樣板(ban)建設(she)確定(ding)各項(xiang)準確數(shu)值,為(wei)后(hou)續實體(ti)(ti)澆(jiao)筑(zhu)提供支(zhi)持(chi)。

為(wei)(wei)保(bao)障優質(zhi)(zhi)(zhi)混凝土(tu)供應(ying),中(zhong)鐵建(jian)工(gong)(gong)(gong)(gong)(gong)集(ji)(ji)團(tuan)(tuan)雄安(an)站(zhan)項(xiang)目(mu)(mu)自建(jian)攪拌(ban)站(zhan);為(wei)(wei)確保(bao)鋼筋原材無任(ren)何銹蝕及(ji)污漬,中(zhong)鐵建(jian)工(gong)(gong)(gong)(gong)(gong)集(ji)(ji)團(tuan)(tuan)雄安(an)站(zhan)項(xiang)目(mu)(mu)自建(jian)7500平米數(shu)(shu)控鋼筋加工(gong)(gong)(gong)(gong)(gong)廠。清水(shui)混凝土(tu)施(shi)工(gong)(gong)(gong)(gong)(gong)關鍵要(yao)細,灌注混凝土(tu)時(shi),技術人員(yuan)詳細記錄(lu)澆注厚(hou)度、振搗次數(shu)(shu)及(ji)位置,成(cheng)型結構物(wu)及(ji)時(shi)覆蓋(gai)粘(zhan)性薄膜(mo),防止因(yin)失水(shui)出現微縫影響外(wai)觀、品質(zhi)(zhi)(zhi),為(wei)(wei)加強施(shi)工(gong)(gong)(gong)(gong)(gong)完成(cheng)率,中(zhong)鐵建(jian)工(gong)(gong)(gong)(gong)(gong)集(ji)(ji)團(tuan)(tuan)雄安(an)站(zhan)項(xiang)目(mu)(mu)開設不同專項(xiang)培訓班,施(shi)工(gong)(gong)(gong)(gong)(gong)人員(yuan)通(tong)過(guo)考核后方可獲(huo)得上崗證,大(da)大(da)降(jiang)低因(yin)不專業(ye)導(dao)致的(de)返工(gong)(gong)(gong)(gong)(gong)次數(shu)(shu)。項(xiang)目(mu)(mu)內(nei)部還設有質(zhi)(zhi)(zhi)量(liang)責(ze)任(ren)制,質(zhi)(zhi)(zhi)量(liang)領導(dao)小組(zu),通(tong)過(guo)質(zhi)(zhi)(zhi)量(liang)網格化(hua)管理將質(zhi)(zhi)(zhi)量(liang)目(mu)(mu)標落至每(mei)名員(yuan)工(gong)(gong)(gong)(gong)(gong)、作業(ye)隊長(chang)、班組(zu)長(chang)。22支隊伍輪班施(shi)工(gong)(gong)(gong)(gong)(gong),13臺泵車隨時(shi)待命。在水(shui)泥施(shi)工(gong)(gong)(gong)(gong)(gong)前,對溫度有較高(gao)要(yao)求(qiu),每(mei)次均先打料塊(kuai),通(tong)過(guo)儀器測(ce)色后方可推(tui)進。中(zhong)鐵建(jian)工(gong)(gong)(gong)(gong)(gong)集(ji)(ji)團(tuan)(tuan)雄安(an)站(zhan)項(xiang)目(mu)(mu)全體安(an)全員(yuan)晝夜不停盯(ding)控,全體技術人員(yuan)根據(ju)現場(chang)實(shi)況及(ji)時(shi)調整(zheng)方案(an)。工(gong)(gong)(gong)(gong)(gong)作高(gao)峰時(shi),建(jian)設者們手拿測(ce)量(liang)工(gong)(gong)(gong)(gong)(gong)具,嚴(yan)格按(an)照數(shu)(shu)百(bai)項(xiang)標準(zhun)逐個測(ce)量(liang)。大(da)伙全力奮戰,爭分奪(duo)秒,全力確保(bao)工(gong)(gong)(gong)(gong)(gong)程施(shi)工(gong)(gong)(gong)(gong)(gong)有序推(tui)進。

得知清水混凝(ning)柱上(shang)的(de)花紋設計帶來了(le)很大的(de)施(shi)工(gong)難(nan)度時,設計師不好意思地對吳(wu)亞(ya)東說(shuo):“給(gei)你們出了(le)個難(nan)題。”“設計方(fang)案肯定是反復(fu)比對后選擇最漂亮的(de)。施(shi)工(gong)過(guo)程再難(nan),我們也會盡力一(yi)試(shi),這就是‘雄安(an)標(biao)準’。”吳(wu)亞(ya)東說(shuo)。

K1快(kuai)速路(lu)項目工(gong)(gong)(gong)期(qi)(qi)只有一年,施(shi)工(gong)(gong)(gong)期(qi)(qi)月(yue)均完成產值(zhi)需達1.3億元,面(mian)對復雜的工(gong)(gong)(gong)程特點(dian)和工(gong)(gong)(gong)期(qi)(qi)壓力,項目將工(gong)(gong)(gong)程一分(fen)為三----主線、東線、西線3大區(qu)、11大勞務分(fen)區(qu)及(ji)224個施(shi)工(gong)(gong)(gong)段的施(shi)工(gong)(gong)(gong)組織(zhi)模式進行管理,并由項目部(bu)領導分(fen)片包(bao)保(bao),壓緊壓實(shi)(shi)責任,倒排工(gong)(gong)(gong)期(qi)(qi),堅決實(shi)(shi)行以日保(bao)月(yue)、以月(yue)保(bao)季、以季保(bao)總工(gong)(gong)(gong)期(qi)(qi)的“兩班倒”晝夜(ye)施(shi)工(gong)(gong)(gong)。確保(bao)施(shi)工(gong)(gong)(gong)生產有序、快(kuai)速推(tui)進。

管(guan)理(li)的(de)先進性,還體現(xian)在現(xian)場施(shi)工(gong)人員(yuan)的(de)生(sheng)活、工(gong)作條件方(fang)面。

中鐵建工集團雄安站項目部工人生活區

“冬天有(you)暖(nuan)氣(qi),夏天有(you)空調,24小時供應(ying)熱(re)水(shui),還有(you)電腦可(ke)以上網,我很(hen)滿意。”來(lai)自河北邯鄲的焊工小伙谷瑞雪(xue)說,他之前在不少工地待過,這里是條件最好的一個(ge)。

中(zhong)鐵(tie)建工集團雄安(an)站(zhan)項目(mu)工人(ren)生活(huo)區占地面積24500平方米(mi),其中(zhong)共有17棟二層樓宿舍(she)(she),房(fang)間576個,高(gao)峰可容納4500名工人(ren)入住。“工人(ren)宿舍(she)(she)都(dou)是免(mian)費的,還配備統一的窗(chuang)簾、櫥(chu)柜(ju)和空調。為了預防(fang)安(an)全隱患,我們把宿舍(she)(she)里的充(chong)電插座都(dou)替換(huan)為了USB接口,為大功率電器設(she)立了專(zhuan)門充(chong)電室(shi),在宿舍(she)(she)中(zhong)就只能給(gei)手機等(deng)電子設(she)備充(chong)電。”中(zhong)鐵(tie)建工集團雄安(an)站(zhan)項目(mu)黨支部(bu)書(shu)記王星運介紹說。

項目還為現場施工(gong)的夫妻檔員工(gong)配(pei)備了(le)夫妻房(fang),35歲的陜西木工(gong)段(duan)紅德,就租下了(le)一間夫妻房(fang),每月只需300元。“我們在(zai)外打工(gong)十多年了(le),上(shang)個月初第一次在(zai)工(gong)地申請到了(le)夫妻宿舍。”

正是得益(yi)于(yu)此,這里的農(nong)民(min)工心情(qing)舒暢,沒(mei)有后顧之憂,能夠專注(zhu)于(yu)工作,為工程的早日高(gao)質量完工貢獻力量。(《國(guo)資(zi)報告》記者 王倩倩)

【責(ze)任編輯:趙(zhao)藝涵(han)】